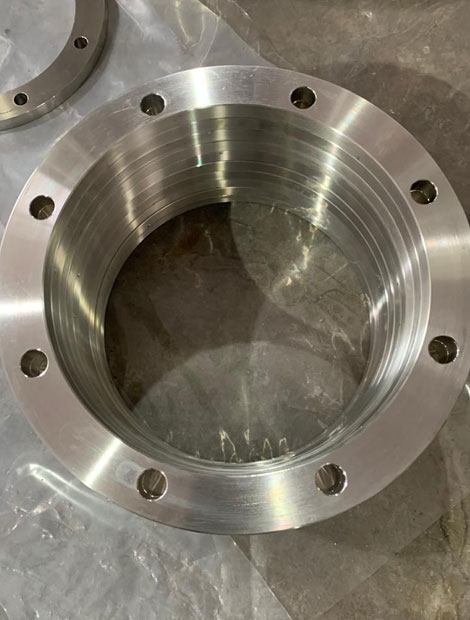

Our Inconel 718 Slip on Flat Face Backing Ring Flanges are used in various industrial sectors such as Chemical processing, Aerospace, Liquid fuel rocket motor components, Pollution-control equipment, Nuclear reactors, Cryogenic storage tanks,Tubing hangers, Well head completion equipment and blow out preventers, Gas turbine engine parts, etc.

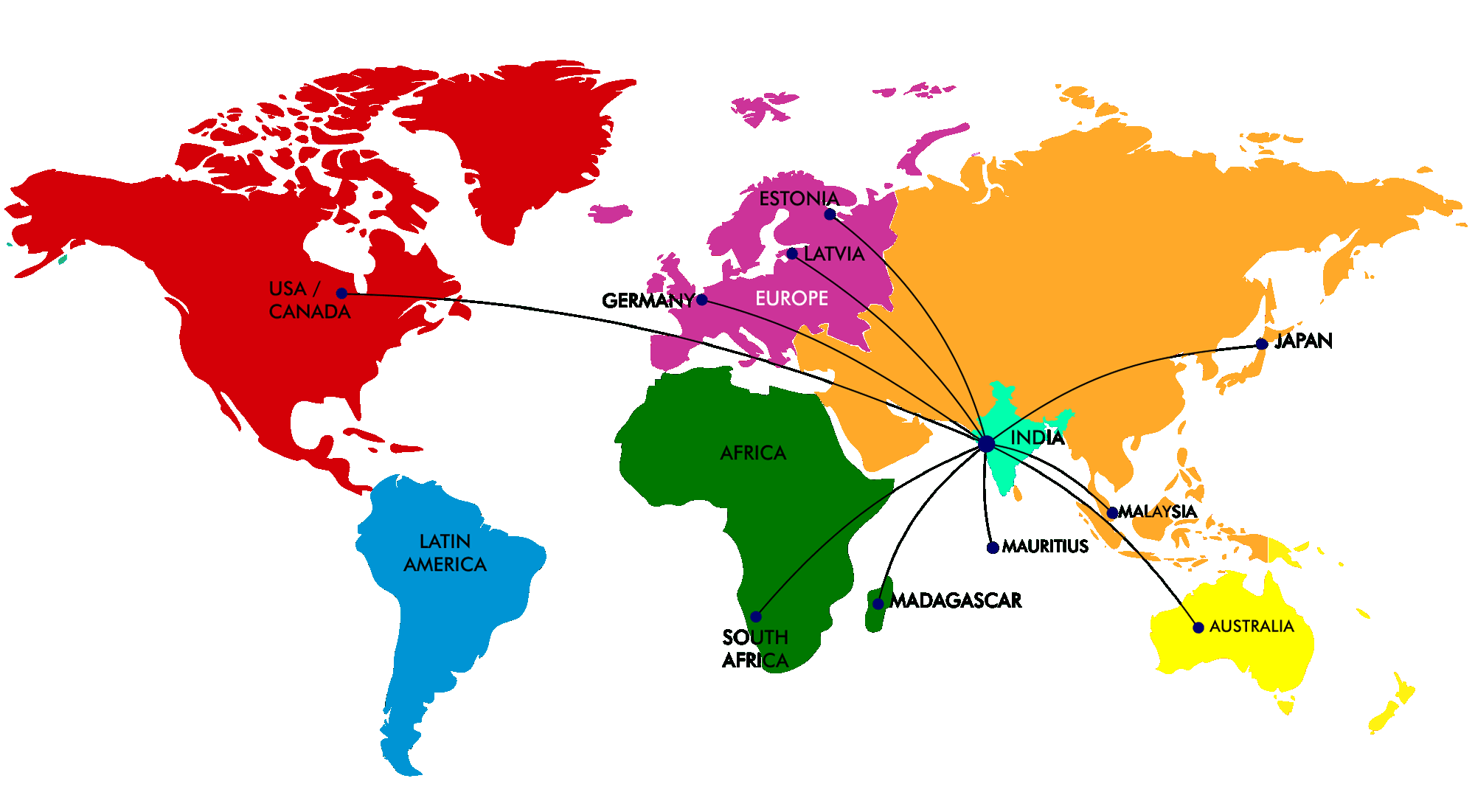

We conduct various tests on our Inconel 718 Backing Ring Flanges to make sure they are suitable for use in various applications right from procurement of raw materials to the final delivery of flanges. The tests conducted include Positive Material Identification Test, Pitting Resistance Test, Flaring Test, IGC Test, Hardness Test, Chemical Analysis, Micro and Macro Test, and so on. We are the leading Inconel 718 Backing Ring Flanges Exporter in various regions like Australia, New Zealand, Dubai, Abu Dhabi, Oman, Saudi Arabia, South Africa, Canada, Qatar, Bahrain, USA, etc.

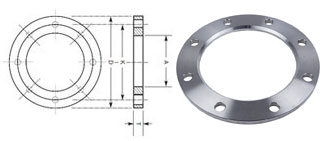

Other Types Of Inconel Alloy 718 Soff Backing Ring Flanges

Inconel Alloy 718 Backing Ring FlangeGrade 718 Backing FlangeASME B16.47 Alloy 718 Backup FlangeInconel 718 Backing Ring FlangesInconel JIS NCF 718 Soff Backup RingAS 2129 Table D, E, F, H Inconel Alloy 718 Back Up Flanges

AS 2129 Table J, K, R, S, & T Ring FlangeInconel Alloy 718 Backup Ring FlangeInconel Alloy 718 Backing Ring FlangesUNS N07718 Stub Flange and Backing RingDIN 2.4668 BRFAS/NZS 4087 PN16 Backing Ring Flanges