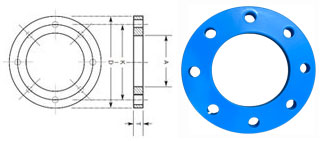

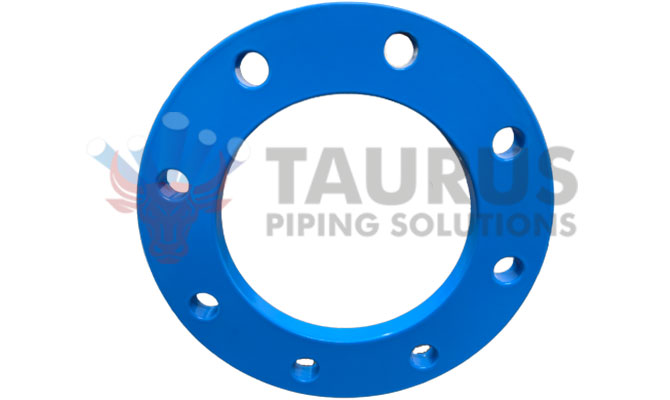

If you need a two-piece nylon coated backing ring flange for a particular line in your system, you can rely on us to provide it. If we don’t have an exact item you require, we will custom manufacture it for you. Our nylon coated backing rings flange are made of standard materials and non-standard alloys. nylon coated backing rings flanges are made to most standard specifications, or configurations, including any national or international standard dimensions.

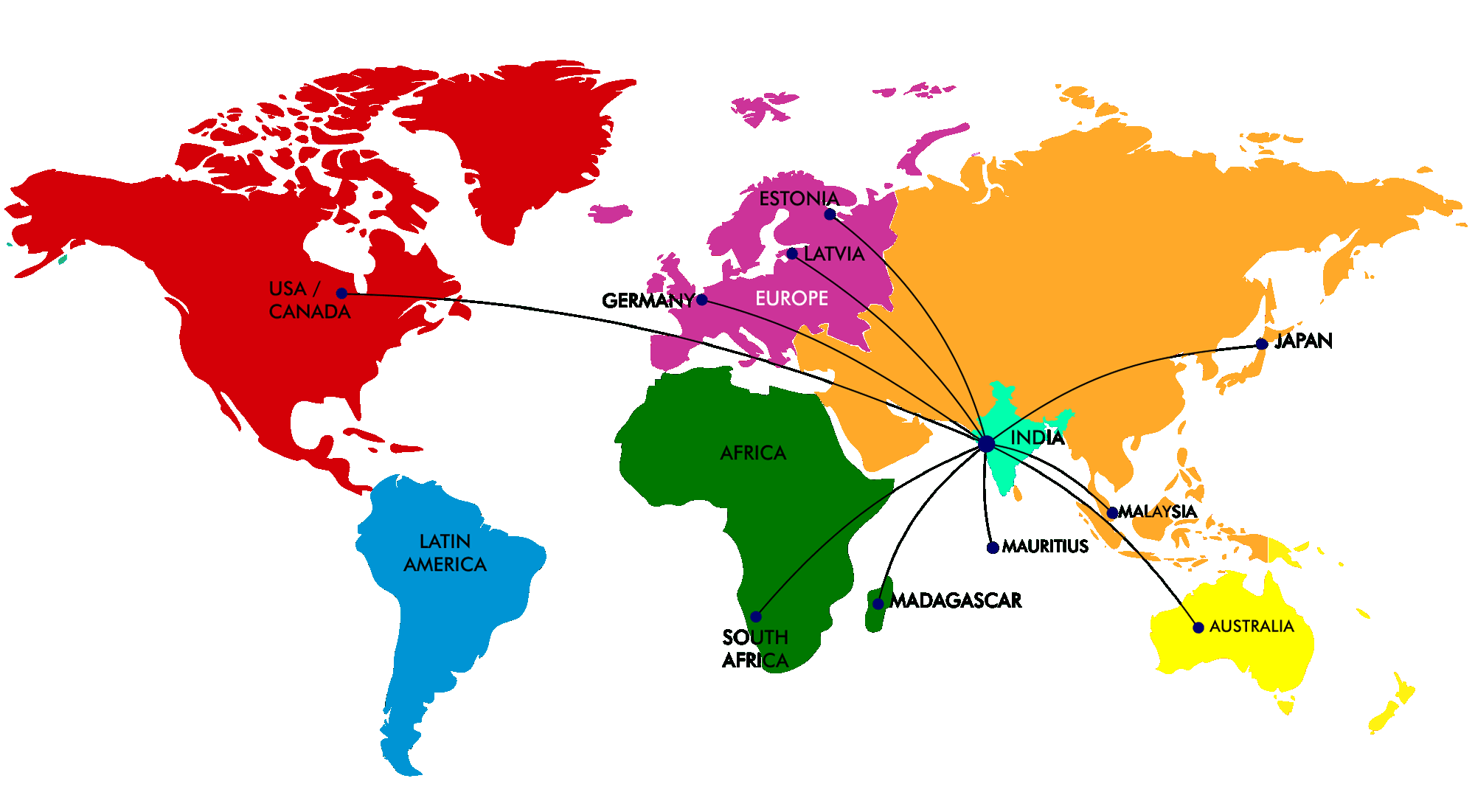

Custom rings can be engineered and produced quickly. Please take the time to browse our catalogs for full range of your most commonly required items. Our Nylon Coated Backing Ring Flanges have been widely accepted across the globe, such as Germany, Netherlands, Denmark, Switzerland, France, Nigeria, Ghana, South Africa, Uganda, Tunisia, Oman etc.

Other Types Of Nylon Coated Backing Ring Flanges

ANSI 150 Nylon Coated Backing RingNylon Coated AS2129, AS4087 Backup FlangeNylon Coated EN1092 PN16 and PN10 BRFNylon Coated BS EN 1092-1 (PN16) Back Up FlangeNylon Coated BS10 (Table-E) Backing FlangeNylon Coated ANSI B16.5 (Class-150) Ring Flange

ANSI 16.5 Nylon Coated Soff Ring FlangeNylon Coated Backing Ring FlangesNylon Coated Table E Backing RingsNylon Coated AS2129 Back Up FlangeNylon Coated PN16, 235 psi Backing FlangeNylon Coated Table D Backing Ring Flange