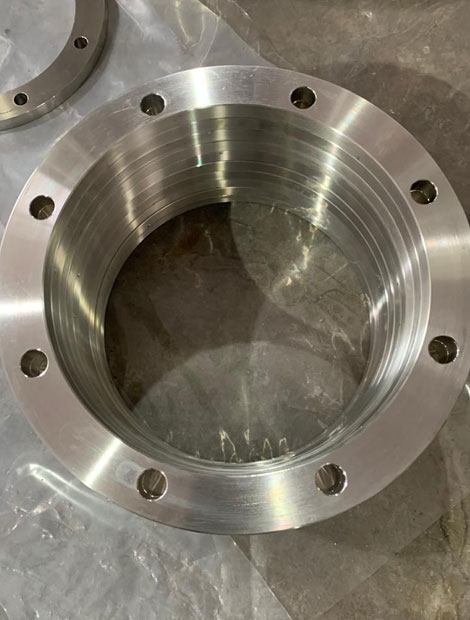

Alloy 601 Backing Ring Flanges adds to a firmly disciple oxide scale which resist spalling even under states of extreme thermal cycling. It has outstanding resistance to aqueous corrosion, high mechanical strength, and is promptly shaped, machined and welded. Inconel 601 Backing Ring Flanges have some excellent properties making it a material of expansive utility in fields like thermal processing, chemical processing, pollution control, aerospace and power generation.

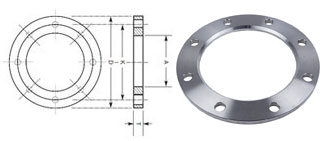

The most important property of Inconel 601 Backing Ring Flanges is resistance to oxidation at very high temperatures up to 1250 degrees C and also in extreme conditions such as cyclic heating and cooling. This is likely because the Inconel UNS N06601 Slip on Flat FaceBacking Ring Flanges have a tightly adhered oxide coating that is resistant to cracking,carburization resistance is strong, also resistant to carbon nitriding conditions.

Inconel 601 Backing Ring Flanges can be used in wide variety of applications such as Chemical Processing, Aerospace, Heat treating industry, Power Generation Industries, catalyst support in nitric acid production, Heat Exchangers, Super Heaters, etc.

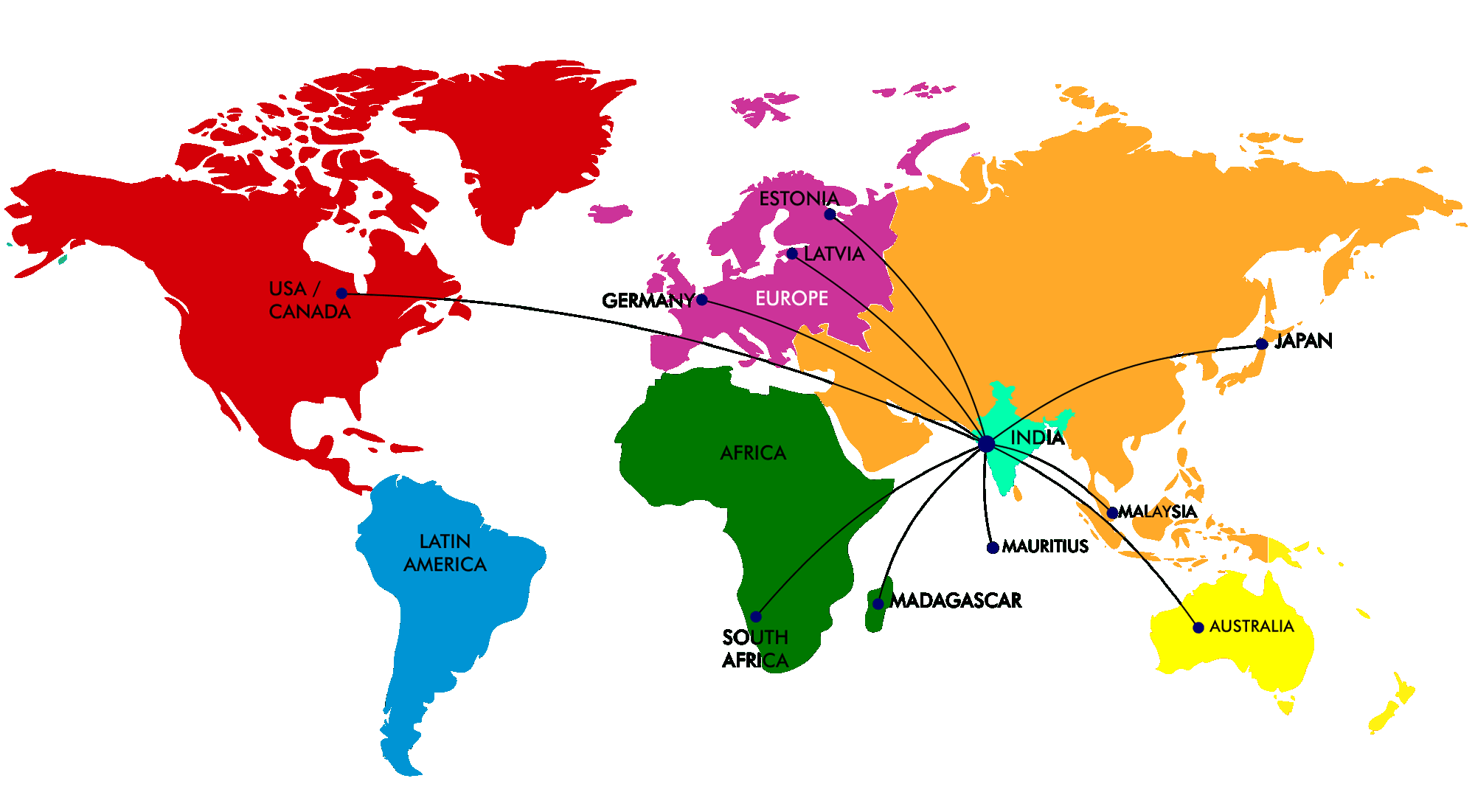

We at Taurus Piping Solutions are the prominentInconel601 Backing Ring Flanges Exporter in various regions like Australia, New Zealand, Dubai, Abu Dhabi, Oman, Saudi Arabia, South Africa, Canada, Qatar, Bahrain, USA, etc.

Other Types Of Inconel Alloy 601 Soff Backing Ring Flanges

Inconel Alloy 601 Backing Ring FlangeGrade 601 Backing FlangeASME B16.47 Alloy 601 Backup FlangeInconel 601 Backing Ring FlangesInconel JIS NCF 601 Soff Backup RingAS 2129 Table D, E, F, H Inconel Alloy 601 Back Up Flanges

AS 2129 Table J, K, R, S, & T Ring FlangeInconel Alloy 601 Backup Ring FlangeInconel Alloy 601 Backing Ring FlangesUNS N06601 Stub Flange and Backing RingDIN 2.4851 BRFAS/NZS 4087 PN16 Backing Ring Flanges